Natural Gas/LPG Boiler

- Model:WNS

- Capacity:0.5t/h-20t/h

- Pressure:0.4MPa~2.5MPa

- Fuel:Natural gas,LPG,CNG,LNG,dual fuel,etc.

- Steam temperature:0℃--226℃,etc

Application:

The Natural Gas/LPG Boiler can be used for the following business:Chemical plant,Textile plant,Food & Beverage,Garment manufacturing,Paper Plant,Printing and dyeing mill,Cement Plant,Fertilizer plant,Feed mills,Rubber factory.Schools,Hotel,Bath Center,Swimming Pool,Hospital,Hotel,etc.

The most important thing is that our boilers are all tailor-made.They are designed all depending on your business,including on the fuel,capacity,pressure and so on you need.

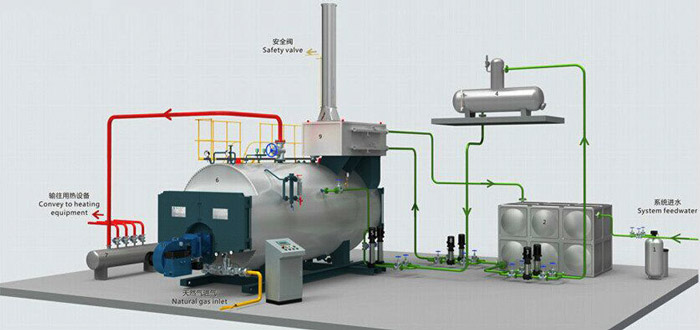

Following are the flowsheet,accessories,valves about the boiler:

Flowsheet:

Characteristics about the boiler:

1.WNS series nature gas and lpg fired steam boiler realize high efficient heat transfer, sufficient burning with brand burner, environment protection

2.Applied international latest technology for big volume combustion room design, and use brand burner machine

3.Corrugated furnace design make large heat transfer area and protect furnace

4.Using spirally corrugated tube , 1-2 faster heat transfer efficiency and remove hidden danger of welding cracks

5.Applied wet-back structure that can reduce faults rate and maintenance cost.

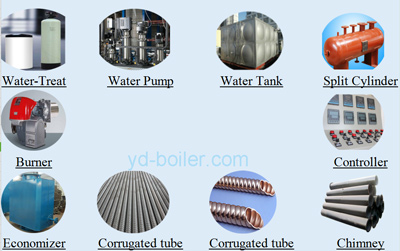

Then,here are the accessories and valves about the Natural Gas/LPG Boiler:

Customer visit:

Intimate tips for you here:

If you still have any question after browsing our website,you can send massege to us,we will give you the best suggestion with regard to you specialized.

Email to me at any time:service@yuanda-boiler.com

1.WNS series nature gas and lpg fired steam boiler realize high efficient heat transfer, sufficient burning with brand burner, environment protection

2.Applied international latest technology for big volume combustion room design, and use brand burner machine

3.Corrugated furnace design make large heat transfer area and protect furnace

4.Using spirally corrugated tube , 1-2 faster heat transfer efficiency and remove hidden danger of welding cracks

5.Applied wet-back structure that can reduce faults rate and maintenance cost.

| 1.WNS Series Steam Boiler Technology Parameter Table |

||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Boiler model | Rated capacity |

Rating pressure |

Feed temperature |

Steam temperature |

Active grate area | Thermal efficiency |

Weight | Dimensions | ||||

| Light oil |

Heavy oil |

Natural gas |

Liquid gas |

City gas |

||||||||

| t/h | MPa | ℃ | ℃ | Kg/h | Kg/h | m3/h | m3/h | m3/h |

% |

Ton | mm | |

| WNS1-1.0-Y(Q) |

1 | 1 | 20 | 184 | 65.5 | 67.3 | 84.2 | 29 | 176 | 99.1 | 4.3 | 3561×1690×1910 |

| WNS 2-1.25- Y(Q) |

2 | 1.25 | 20 | 194 | 129.6 | 132.2 | 165 | 57.3 | 346 | 99.1 | 7.2 | 4111×1950×2199 |

| WNS3-1.25-Y(Q) |

3 | 1.25 | 20 | 194 | 192 | 195 | 250 | 82 | 510 | 99.1 | 8 | 4330×2248×2564 |

| WNS4-1.25- Y(Q) |

4 | 1.25 | 20 | 194 | 256 | 261.9 | 323.6 | 109 | 682 | 99.2 | 9.6 | 4732×2150×2448 |

| WNS5-1.25- Y(Q) |

5 | 1.25 | 20 | 194 | 318 | 322 | 386 | 140 | 87 | 93.1 | 12.5 | 5970×2360×2796 |

| WNS6-1.25- Y(Q) |

6 | 1.25 | 20 | 194 | 380 | 390.6 | 450 | 164 | 1020 | 99.2 | 16.5 | 5500×2600×2990 |

| WNS8-1.25- Y(Q) |

8 | 1.25 | 105 | 194 | 503 | 517 | 642 | 209 | 1321 | 99.23 | 24.8 | 6450×2800×3200 |

| WNS10-1.25- Y(Q) |

10 | 1.25 | 105 | 194 | 628 | 643 | 805 | 264 | 1654 | 99.5 | 26.8 | 6800×2900×3394 |

| WNS15-1.25- Y(Q) |

15 | 1.25 | 105 | 194 | 940 | 965 | 1182 | 400 | 2417 | 99.5 | 38 | 7150×3200×3540 |

| WNS20-1.25- Y(Q) |

20 | 1.25 | 105 | 194 | 1250 | 1301 | 1597 | 520 | 3299 | 99.5 | 55 | 8200×3400×3826 |

Chinese

Chinese

English

English