Wood pellet & Charcoal Steam boiler

- Model:SZL1-1.0-T,SZL20-1.25-T,etc.

- Capacity:0.5t/h-20t/h

- Pressure:Up to 2.5Mpa

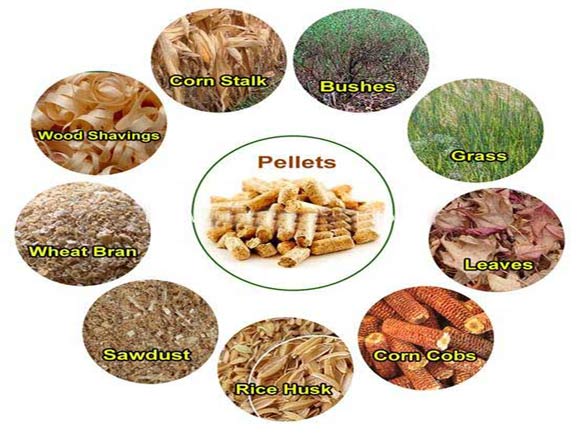

- Fuel:Biomass,pellet,wood chips,rice husk,sawdust,peanut shell,palm oil shell,coconut shell,straw,corncob,bagasse,etc.

- Steam temperature:Up to 226℃

Application:

The Wood pellet/Charcoal Steam boiler can be used for the following business:Chemical plant,Textile plant,Food & Beverage,Garment manufacturing,Paper Plant,Printing and dyeing mill,Cement Plant,Fertilizer plant,Feed mills,Rubber factory.Schools,Hotel,Bath Center,Swimming Pool,Hospital,Hotel,etc.

The most important thing is that our boilers are all tailor-made.They are designed all depending on your business,including on the fuel,capacity,pressure and so on you need.

Following are the diagrams,accessories,valves about the boiler:

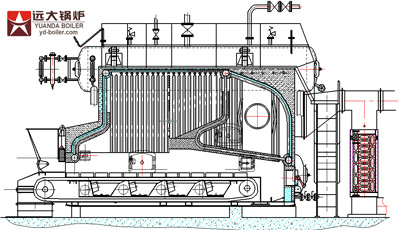

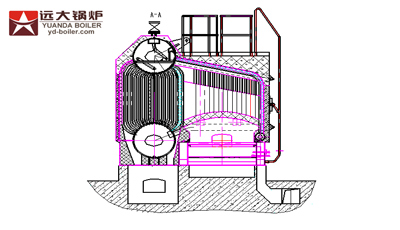

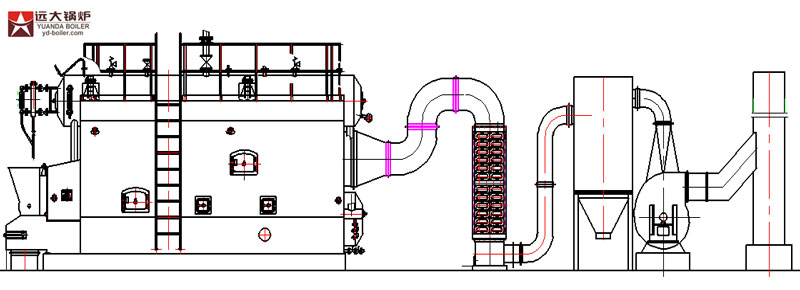

Diagrams:

1.Double drum water pipe: independent offset furnace design - meet volatile strong characteristics of biomass fuel combustion rate is high, the state guarantees the boiler output;

2.cyclone combustion chamber state - cyclone gravity dust removal, secondary combustion, state to achieve the level of dust removal in the boiler;

3.the intelligent control - make boiler operation safer;

4.the big hopper design - ensure the continuity of fuel supply;

5.large porous link - cloth uniform wind, simple maintenance.

Then,here are the accessories and valves about the Wood pellet/Charcoal Steam boiler:

Customer visit:

Intimate tips for you here:

If you still have any question after browsing our website,you can send massege to us,we will give you the best suggestion with regard to you specialized.

Email to me at any time:service@yuanda-boiler.com

1.Double drum water pipe:independent offset furnace design - meet volatile strong characteristics of biomass fuel combustion rate is high, the state guarantees the boiler output;

2.cyclone combustion chamber state - cyclone gravity dust removal, secondary combustion, state to achieve the level of dust removal in the boiler;

3.the intelligent control - make boiler operation safer;

4.the big hopper design - ensure the continuity of fuel supply;

5.large porous link - cloth uniform wind, simple maintenance.

| Steam Boiler SZL Series specification --- D-type Double drum water tube structure | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Model | Rating capacity | Rating pressure | Feed water temperature | Rating steam temperature | Active grate area | Boiler heating area | Boiler efficiency | Fuel consumption | Weight | Dimension | Package method |

| t/h | Mpa | ℃ | ℃ | ㎡ | ㎡ | % | kg/h | t | mm | ||

| SZH2-1.25/2.5-AII | 2 | 1.25/2.5 | 20 | 194/226 | 2.78 | 69.5 | 81 | 225/228 | 17/18.5 | 4850×2690×3468 | Package bolier |

| SZH4-1.25/2.5-AII | 4 | 1.25/2.5 | 20 | 194/226 | 4.5 | 119.2 | 81 | 450/462 | 22/24.8 | 5450×3040×3468 | |

| SZL2-1.25/2.5-AII | 2 | 1.25/2.5 | 20 | 194/226 | 3.1 | 64.6 | 81.6 | 223/227 | 20/25 | 5960×2960×3468 | |

| SZL4-1.25/2.5-AII | 4 | 1.25/2.5 | 20 | 194/226 | 4.6 | 115.3 | 81.6 | 447/453 | 28/29 | 6510×3130×3468 | |

| SZL6-1.25/2.5-AII | 6 | 1.25/2.5 | 20 | 194/226 | 7.3 | 136.3 | 81.6 | 671/684 | 38/42 | 7830×3346×3468 | |

| SZL8-1.25/2.5-AII | 8 | 1.25/2.5 | 20 | 194/226 | 10.4 | 173 | 81.8 | 781/803 | 52 | 8200×3346×3468 | |

| SZL10-1.25/2.5-AII | 10 | 1.25/2.5 | 20 | 194/226 | 11.8 | 233 | 82 | 1113/1127 | 68 | 8500×3346×3482 | Assembled boiler |

| SZL15-1.25/2.5-AII | 15 | 1.25/2.5 | 20 | 194/226 | 17.7 | 307.3 | 82.3 | 1663/1686 | 30 | 9583×3400×3550 | |

| SZL20-1.25/2.5-AII | 20 | 1.25/2.5 | 20 | 194/226 | 20.8 | 725.2 | 82.3 | 2218/2246 | 40 | 11600×3460×3520 | |

| SZL series (type D) hot water boiler technology parameter table | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Boiler model | Rated thermal power | Rating pressure | Rated outlet temperature | Return water temperature | Active grate | Exhaust gas temperature | Design efficiency | Water volume | Weight | Dimension | Delivery mode |

| MW | MPa | ℃ | ℃ | ㎡ | ℃ | % | ㎡ | T | mm | ||

| SZL1.4-0.7/95/70-AII | 1.4 | 0.7 | 95 | 70 | 2.78 | 69.5 | 81 | 211 | 17 | 4850×2690×3462 | Package |

| SZL2.8-0.7/95/70-AII | 2.8 | 0.7 | 95 | 70 | 4.5 | 119.2 | 81 | 423 | 22 | 5450×3040×3462 | Package |

| SZL4.2-1.0/95/70-AII | 4.2 | 1 | 95 | 70 | 7.8 | 171 | 81 | 8.2 | 25 | 6100×3400×3500 | Package |

| SZL5.6-1.0/95/70-AII | 5.6 | 1 | 95 | 70 | 10.1 | 170 | 81 | 10.7 | 29 | 6800×3400×3500 | Package |

| SZL7-1.0/115/70-AII | 7 | 1 | 115 | 70 | 11.8 | 146 | 82 | 13.8 | 31 | 7600×3400×3500 | Assembled |

| SZL10.5-1.0/115/70-AII | 10.5 | 1 | 115 | 70 | 17.3 | 157 | 82 | 17.6 | 42 | 9800×3400×3540 | Assembled |

| SZL14-1.0/115/70-AII | 14 | 1 | 115 | 70 | 21 | 158 | 82 | 24.6 | 50 | 11000×3400×3540 | Assembled |

| SZL17.5-1.0/115/70-AII | 17.5 | 1 | 115 | 70 | 25.8 | 159 | 83 | 31 | 52 | 8300×3000×3600 | Assembled |

| Notes: Coal consumption counted by standard coal, parameters for reference only, and if the technology is improved, please refer to random technical parameters. | |||||||||||

Chinese

Chinese

English

English