DZL Coal Steam Boiler

- Model:DZL

- Capacity:0.5t/h-20t/h

- Pressure:0.4MPa--2.5MPa

- Fuel:Coal, solid fuel, anthracite, bitumite, lignite, etc.

- Steam temperature:0℃--226℃,etc

Application:

The DZL Coal Steam Boiler can be used for the following business:Chemical plant,Textile plant,Food & Beverage,Garment manufacturing,Paper Plant,Printing and dyeing mill,Cement Plant,Fertilizer plant,Feed mills,Rubber factory.Schools,Hotel,Bath Center,Swimming Pool,Hospital,Hotel,etc.

The most important thing is that our boilers are all tailor-made.They are designed all depending on your business,including on the fuel,capacity,pressure and so on you need.

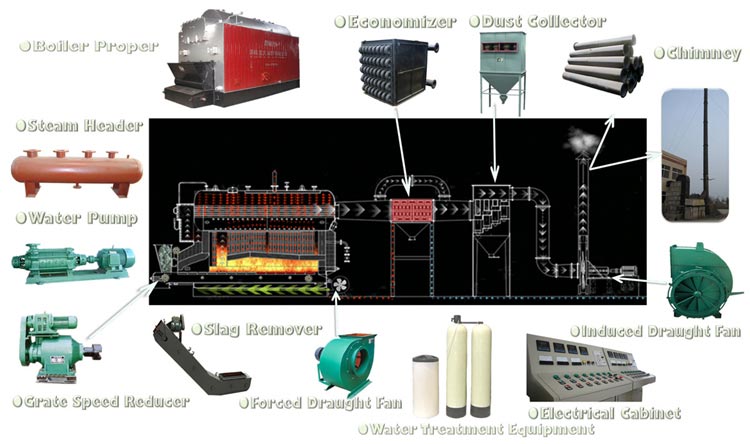

Following are the drawing,accessories,valves about the boiler:

Drawing:

Details about the boiler:

1.Fuel:Coal,solid fuel,anthracite,bitumite,lignite

2.DZL Chain grate stoker boiler,automatic burning

3.Single drum,water tube and fire tube boiler

4.Sufficient and Steady Capacity

5.Rapid Warming and High Heat Efficiency

6.Low Original Dust Discharge Concentration, Environmental Protection and Energy Conservation

7.High Steam Quality

8.Strong Water Quality Adaptability

9.Small Overall Dimensions and Low Boiler Room Investment Cost

10.Low Operating Cost, Safety and Reliability

11.Short Installation Time, Low Installation Cost.

Then,here are the accessories and valves about the DZL Coal Steam Boiler:

Customer visit:

Intimate tips for you here:

If you still have any question after browsing our website,you can send massege to us,we will give you the best suggestion with regard to you specialized.

Email to me at any time:service@yuanda-boiler.com

1.Sufficient and Steady Capacity

2.Rapid Warming and High Heat Efficiency

3.Low Original Dust Discharge Concentration, Environmental Protection and Energy Conservation

4.High Steam Quality

5.Strong Water Quality Adaptability

6.Small Overall Dimensions and Low Boiler Room Investment Cost

7.Low Operating Cost, Safety and Reliability

8.Short Installation Time, Low Installation Cost

| Boiler Model | Rated |

Rated |

Feed water temperature |

Steam |

Active |

Exhaust |

Design |

Fuel |

Main part |

Main part |

Delivery Mode |

|---|---|---|---|---|---|---|---|---|---|---|---|

| t/h | MPa | ℃ | ℃ | ㎡ | ℃ |

% |

Kg/h | Ton | mm | ||

| DZL1-1.0-AII | 1 | 1 | 20 | 184 | 1.85 | 157 | 80 | 118 | 14.2 | 5488×2200×2832 | Package |

| DZL2-1.25-AII | 2 | 1.25 | 20 | 194 | 3.4 | 163 | 80 | 238 | 23.2 | 5900×2500×3256 | Package |

| DZL4-1.25-AII | 4 | 1.25 | 60 | 194 | 5.18 | 180 | 80 | 472 | 28 | 6829×2550×3484 | Package |

| DZL6-1.25-AII | 6 | 1.25 | 60 | 194 | 7.55 | 166 | 80 | 685 | 47.6 | 7695×3180×4074 | Package |

| DZL10-1.25-AII | 10 | 1.25 | 105 | 194 | 12 | 151 | 80 | 1128 | 56 | 7746×3773×3441 | Assembled |

| DZL15-1.25-AII | 15 | 1.25 | 105 | 194 | 18 | 161 | 81 | 1698 | 18.8 | 8650×2300×2500 | Assembled |

| DZL20-1.25-AII | 20 | 1.25 | 105 | 194 | 22.9 | 150 | 81 | 2241 | 19.1 | 8915×3373×3337 | Assembled |

Chinese

Chinese

English

English