Biomass burner boiler

- Rating pressure(MPa):0.4MPa--2.5MPa

- Feed temperature(℃):20

- Steam temperature(℃):0℃--226℃

- Pellet consumption(Kg/h):150; 300; 450...

Application:

The Biomass burner boiler can be used for the following business:Chemical plant,Textile plant,Food & Beverage,Garment manufacturing,Paper Plant,Printing and dyeing mill,Cement Plant,Fertilizer plant,Feed mills,Rubber factory.Schools,Hotel,Bath Center,Swimming Pool,Hospital,Hotel,etc.

The most important thing is that our boilers are all tailor-made.They are designed all depending on your business,including on the fuel,capacity,pressure and so on you need.

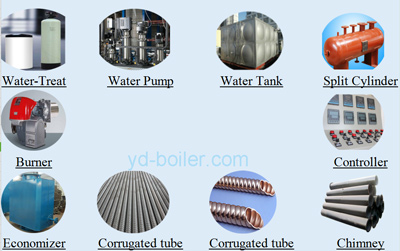

Following are the accessories,valves about the boiler:

Biomass pellet is sent into the combustion chamber according to loading size by feeder, the whole combustion operation process is like to fire gas or oil in automatic control; It only take 40 minutes to boost the pressure from 1bar to 8bar; the exhausted smoke is pure white without dust collector, if equip with duct collector, the exhausted smoke can fully meet the requirements of the environmental protection; our company have succeed in many projects of the biomass burner with our WNS series boiler, it's a new and effective project.

If you don't want to use biomass pellet, just need to change the biomass burner to gas/oil boiler, more convenient and more fuel choices

Then,here are the accessories and valves about the Biomass burner boiler:

Customer visit:

Intimate tips for you here:

If you still have any question after browsing our website,you can send massege to us,we will give you the best suggestion with regard to you specialized.

Email to me at any time:service@yuanda-boiler.com

1. The biomass burning boiler Integrated the advantages of chain type biomass boiler and gas boiler.It is biomass fuel boiler of low cost, energy conservation, environmental protection and thermal efficiency can reach above 90%.

2. Installation is simple, maintenance is convenient.

3. The structure of three return, threaded pipe technology and the characteristics of the wet back structure, increase the heating area. improve the efficiency of the boiler.

| Boiler model | Rated capacity |

Rating pressure |

Feed temperature |

Steam temperature |

Pellet consumption | Thermal efficiency |

Weight | Dimensions |

|---|---|---|---|---|---|---|---|---|

| t/h | MPa | ℃ | ℃ | Kg/h |

% |

Ton | mm | |

| WNS1-1.0-T | 1 | 1 | 20 | 184 | 150 | 91 | 4.3 | 3561×1690×1910 |

| WNS 2-1.25- T | 2 | 1.25 | 20 | 194 | 300 | 92 | 7.2 | 4111×1950×2199 |

| WNS3-1.25-T | 3 | 1.25 | 20 | 194 | 450 | 92.1 | 8 | 4330×2248×2564 |

| WNS4-1.25- T | 4 | 1.25 | 20 | 194 | 600 | 93 | 9.6 | 4732×2150×2448 |

| WNS5-1.25- T | 5 | 1.25 | 20 | 194 | 750 | 93 | 12.5 | 5970×2360×2796 |

Chinese

Chinese

English

English